Post-Grad Work @ KLA

What is KLA?

KLA is a large, multinational company in the semiconductor industry. KLA produces quality control tools to inspect wafers and reticles (lithography tools used to make microchips) to check for defects. KLA sells these tools to companies such as Samsung and Intel.

Hired: March 2020

Job title: Associate Test Engineer III

Team: KLA’s RAPID Team working on next-gen reticle inspection tools

My responsibilities fall under 3 sections:

CSAM Machine

Engineering a standard-use processes for this new tool and optimizing for my team’s unique application

Parts preparation Steps

Overseeing and engineering improvements to the preparation steps for our build parts. Including inspection, different types of metrology, thin film sputter steps, organization/storage, etc.

Inventory

Trusted to oversee the sub-system’s inventory of ~3,000 exotic material, low tolerance parts worth multiple millions

CSAM Machine

This is the CSAM (Confocal Scanning Acoustic Microscopy) tool which uses ultrasound to "see through" materials. My team at KLA purchased this tool to analyze the bond quality of soldered components on ceramic boards. These ceramic boards are part of the heart of KLA's most expensive and ambitious product to date: a cutting edge, high throughput, scanning electron microscope (SEM) for reticle inspection. Because my team was stretched so thin, I was assigned to calibrate the CSAM tool and engineer a standard-use process. Management wanted this job completed last week, but bad data gathered from this tool could cost the team around $1M and have serious effects on the project timeline. The pressure was on. In the end, I was able to create an accurate, efficient, and user-friendly process for our unique application. I was able to do this by not only learning the ins and outs of the tool, but also by self-teaching myself the physics behind acoustic microscopy to optimize and fully understand the data gathered. This job should have never been given to a recent-grad, and was well above my paygrade, but I am very proud to say the objectives were completed in a timely manner.

Parts Preparation Steps

Near the start of my employment, I was asked to perform the parts preparation steps for a wide variety of high-dollar parts. This includes receiving the parts, unpacking, inspection, metrology, cleaning, bake-out, GCMS testing (Gas Chromatography Mass Spectrometry), storage, and inventory.

After becoming comfortable with the processes, I was asked to find improvements, propose improvements, and implement improvements. After the process was optimized, I would write detailed, easy-to-follow procedures.

Nikon tool

The Nikon VMR-H tool was used to optically measure critical dimensions on our parts. After becoming proficient with the complicated software, I created many different measurement recipes so the process could be done efficiently and semi-automatically by future non-engineer users.

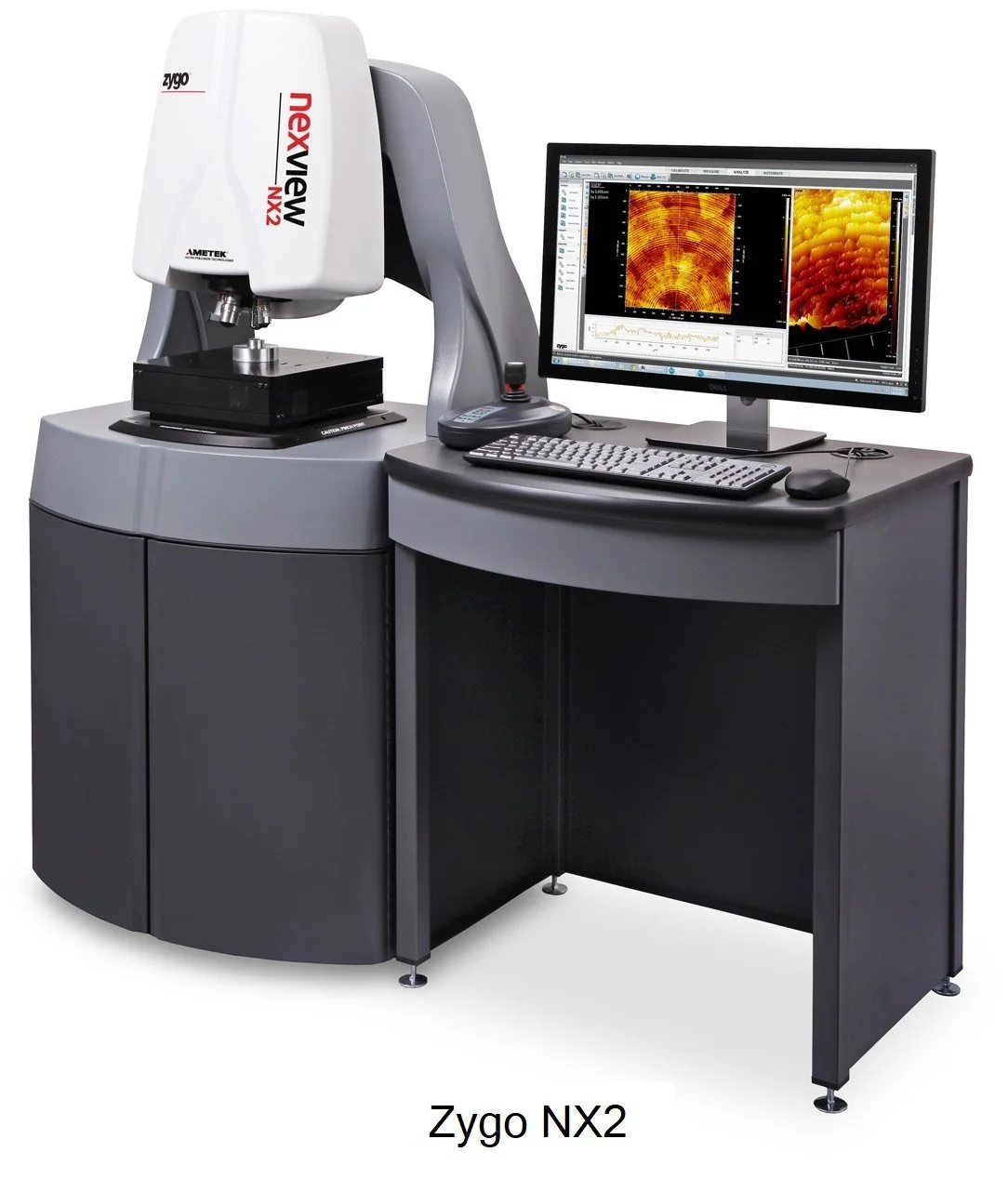

Zygo Tool

The Zygo NX2 tool uses White Light Interferometry (WLI) which can give the user detailed topographical data down to nanometer levels. Being the only member of our team trained on this tool, I would use this tool extensively to produce data which would help solve the plethora of problems encountered on this project.

Inventory

After my co-worker changed jobs, my manager trusted me to take over her inventory duties. This includes about 200 unique parts, made out of exotic materials, costing scary amounts of money, with long lead times to acquire.

I immediately found ways to improve the inventory tracking methods which the previous co-worker was using. I created many different excel trackers (picture to right) to track the parts count, location, and how far through the preparation processes they are. I also created forecast tackers to see when we need to order more parts.

These trackers proved to be extremely helpful to our team. Multiple times our materials team would be behind and forget to order essential parts. With my forecast tracker, I could easily see what’s missing and help the team avoid a huge issue.